Bacteriophages – An effective tool to control Salmonella and pathogenic E. coli in milling operation

by Amit Vikram, Ph. D., Intralytix, Inc.

Intralytix

Intralytix is a world leader in bacteriophage (or phage) technology and has developed phage preparations SalmoFresh™ and EcoShield™ PX, targeting Salmonella and Shiga-toxin producing E. coli (STEC) respectively, among other phage products.

Introduction

The milling industry does not typically employ targeted antimicrobial intervention believing flour is a low-risk product and subject to heat treatment constituting a kill step in preparation of food products either commercially or in the consumer kitchen. However, recent outbreaks and recalls associated with flour and related products have challenged this paradigm. In 2019, the US Food and Drug Administration (FDA) issued 14 notices for recalls of flour. Of these recalls, 12 were associated with Shiga-toxin producing E. coli (STEC) and 2 were due to presence of Salmonella. Indeed, several studies have now demonstrated that STEC and Salmonella can survive and contaminate the four and flour-products – leading to concerns related to flour-borne outbreak of these pathogens. Recalls of the flour products are costly and may come with a price tag of $5-$10 million per recall and at the same time tarnish the brand and company reputation. The risk of flour associated microbial detection, outbreak and traceability has increased the need for development of intervention strategies.

Recently some millers have started experimenting with various chemical-based antimicrobials. These chemicals reduce the pathogens to varying degrees but may impact the flour functionality and/or organoleptic properties. For example, the use of organic acid at the tempering stage at the concentrations reported to achieve meaningful reductions may impact baking qualities. Another problem associated with the use of acid-based products is corrosion of equipment and other surfaces these chemicals contact. For example, continuous use of chlorine and other antimicrobials is known to corrode steel surfaces. The corrosion results in increased surface roughness which provides niche for bacteria to attach and form biofilms. Biofilms then become a recurrent source of contamination and accelerate the corrosion further damaging the equipment. Biofilms have also been observed on the interior of milling equipment surfaces such as roller mill housings and sifter box interiors. Removal of these biofilms requires higher concentrations of chemicals which then cause further corrosion which may become a downward cycle. Corrosion is also likely to reduce the equipment life. Secondly, certain chemicals can be hazardous to worker and require a rigorous safety procedure to be in place for their use.

Definition of Bacteriophage

Bacteriophages are fascinating microorganisms in the Kingdom “Virus”. The word “Bacteriophage” is derived from bacteria and Greek phagein, meaning to devour. Phages are ubiquitous in nature and are present in food, skin, and gut among other niches. For example, an estimated 10 billion phage particles per gram are present in the human gut. Phages are natural predators of bacteria and highly specific to their target. For example, Salmonella targeting phages like those present in SalmoFresh™ will only lyse (destroy) Salmonella but not adversely affect other bacteria, yeast, humans, plants, and animals. Phage biocontrol has emerged as an effective alternative green technology to reduce or eliminate foodborne pathogens and is currently used by different food industries processing poultry, meat, fish, and fresh produce.

How Bacteriophage Work

In essence, bacteriophages are a natural biocontrol mechanism where a naturally occurring highly specialized microorganism is used to kill a target pathogen and do not impact equipment any more than the water used in the tempering process. Phages exert their effect in a short time and multiply 10-200-fold or more on the target bacteria, killing the host in the action. Bacteriophages can also penetrate biofilms killing target pathogens. Chemical-antimicrobials on the other hand have a short active lifespan, performing the killing action within few minutes of application and, are rendered inactive (quenched) after each encounter with organic material including wheat kernel surface.

Phage Performance Test

While bacteriophage use in other industries such as poultry, meat and fresh produce is well established, the effectiveness of phage application in milling operation has not been demonstrated. Laboratory tests showed that both SalmoFresh™ and EcoShield™ PX reduce the Salmonella and STEC levels by 99% (2 logs), respectively, after one hour of wheat tempering.

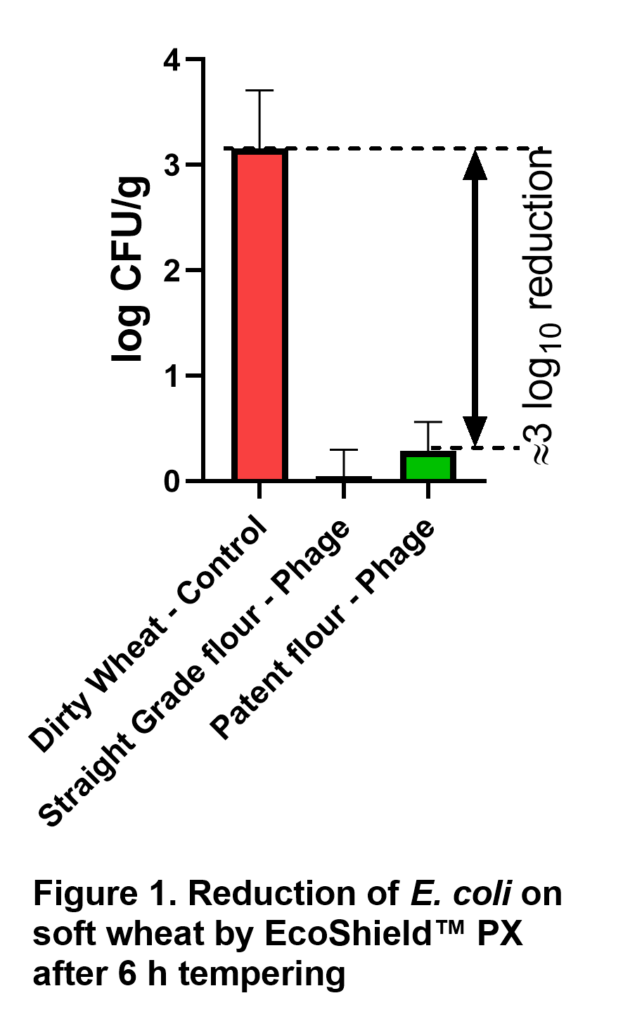

A commercial mill test was set up with more than 900 bushels (25MT) of wheat grains tempered for 6 hours prior to milling. EcoShield™ PX was applied at the rate of 1X or 10 million phage particles per g, by adding it to the tempering water just prior to the tempering device. The dirty wheat was inoculated with 5-log per gram of generic, non-pathogenic E. coli strain prior to cleaning so as not to introduce a pathogen in the commercial milling process. The commercial mill test was even more effective and demonstrated a higher efficacy of 99.9% (3 log) reduction in levels of a challenge generic E. coli strain (Figure 1) compared to the lab tests.

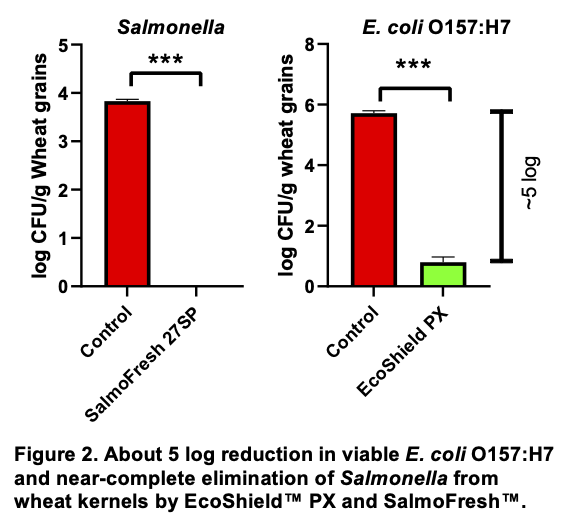

EcoShield™ PX is highly specific to STEC strains but is 40% less effective against the generic strain used in the commercial mill test. Therefore, it is highly likely that a 3-log efficacy observed in the commercial mill test would be greater, had an actual STEC or pathogen been present. At higher concentrations phage products can achieve a 5-log reduction in pathogen level. For example, Figure 2 shows a 5-log reduction by higher concentrations of SalmoFresh™ and EcoShield™ PX.

Performance of Phage-Treated Flour

Pathogen interventions must not only result in pathogen reduction but maintain product functionality. The chemical and physical properties of phage-treated flour were similar to untreated flour (Table 1) indicating hydration performance and baking qualities were not affected by phage treatment. Phage treatment did not impact the texture, flavor, odor in cookie and pancake baking/cooking tests (Figure 3).

Table 1. Chemical and physical properties of untreated and phage-treated straight grade and patent flour

| Moisture | Ash | Protein | Cookie Bake | Water Absorption | Sodium Carbonate | Sucrose | Lactic Acid | Gluten Perf Index | |

| Straight Grade Flour -Control | 12.72 | 0.5 | 8.31 | 8.281 | 56.41 | 70.26 | 92.74 | 88.56 | 0.543 |

| Straight Grade Flour- Treated | 12.92 | 0.504 | 8.2 | 8.301 | 56.37 | 70.06 | 93.57 | 89.05 | 0.544 |

| Patent Flour – Control | 12.92 | 0.43 | 7.82 | 8.882 | 54.49 | 67.61 | 89.65 | 96.95 | 0.616 |

| Patent Flour -Treated | 13.12 | 0.411 | 7.76 | 8.896 | 54.26 | 70.13 | 91.23 | 94.69 | 0.587 |

Summary

In summary, phages (i) are very effective in reducing Salmonella and E. coli in commercial mill, (ii) do not impact flour functionality, (iii) are safe for workers and equipment and do not require extensive safety protocol, and (iv) easy to apply during tempering, which consists of adding phage solution to incoming tempering water. An added benefit of using SalmoFresh™, EcoShield™ PX or a combination product Nature’s Grain Guard™ is that these are FDA cleared GRAS and certified organic, kosher and halal and therefore can be applied on products that require ingredients with these labels.

SalmoFresh™ and EcoShield™ PX and Nature’s Grain Guard™ are products of Intralytix, Inc., Columbia, MD.

Acknowledgements

Intralytix, Inc., Columbia MD- Mary Theresa Callahan, Joelle Woolston, Greg Strang, Alexander Sulakvelidze

Lesaffre Yeast Corporation, Milwaukee, WI- Kristen Irsik, Joanne Sullivan, John Philips, Dean Modglin

Siemer Milling Company, Teutopolis IL-Mary Gleason, Lucy Wang, Richard Gillespi, Daphne Gullett, Red Tegeler, David Jansen

JAG Services Inc., Lawrence KS-Jeff Gwirtz